Khoom Taw Qhia

Peb muab emi fingerstock ntawm zoo heev conductivity, Peb muaj ntau tshaj 16 xyoo ntawm kev paub nyob rau hauv EMI fingstock manufacturing thiab ua tiav cov txheej txheem khiav, nrog tshaj 300 tus qauv EMI gasket khoom.

Khoom Parameter

|

|

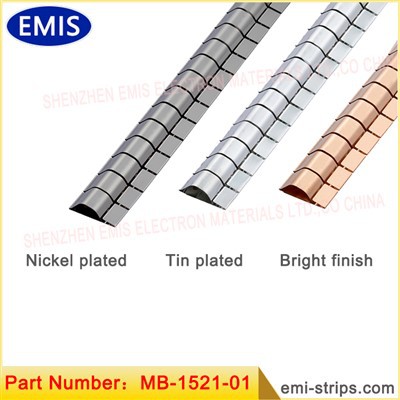

Tshooj Naj Npawb |

T (mm) |

A |

B |

C |

R1 |

R2 |

P |

S |

Lmax |

Nodes |

Xim Xim |

|

MB -1077-01 |

0.05 |

4.8 |

1.7 |

1.35 |

0.32 |

2.15 |

4.61 |

0.51 |

230 hli |

50 |

Bright tiav |

|

MB-1077-0S/N |

0.05 |

4.8 |

1.7 |

1.35 |

0.32 |

2.15 |

4.61 |

0.51 |

230 hli |

50 |

-0S: Tin / -0N: Nickel |

|

MB -1077-01 |

0.05 |

4.8 |

1.7 |

1.35 |

0.32 |

2.15 |

4.61 |

0.51 |

4 05mm |

88 |

Bright tiav |

|

Re: Ntev tuaj yeem txiav rau hauv X nodes, X=1.2.3.4..., Qhov saum npoo kuj tuaj yeem plated nrog kub. Silver & Zinc thiab lwm yam |

|||||||||||

Khoom feature thiab daim ntawv thov

emi fingerstock muaj qhov zoo conductivity, siab tensile elasticity, siab shielding nyhuv, zoo corrosion kuj, ntev kev pab cuam lub neej, thiab yooj yim installation.

Tus nqi-zoo, ntau yam kev xaiv electroplating, kev ua haujlwm zoo heev ntawm qhov kub thiab txias, tiv taus ya raws thiab UV hluav taws xob

EMI shielding gasket Khoom yog siab beryllium tooj liab cov ntaub ntawv nrog zoo elasticity, Me me hneev taw ntawm PCB, hloov phau ntawv ua hauj lwm nrog SMT

Kev tsim tshwj xeeb sab nrauv, ntxiv rau qhov ua tau zoo, Ua haujlwm zoo dua hauv EMI, ESD, lossis teeb liab kis

Nws muaj qhov sib tiv tauj loj, cov nyhuv EMI zoo, vuam yooj yim, thiab cov khoom lag luam ntseeg tau zoo

Cov lus qhia ntau lawm

Flow Electromagnetic Interference (EMI) yog ib qho kev sib tw hauv cov khoom siv hluav taws xob thiab cov tshuab, feem ntau ua rau muaj kev cuam tshuam tsis zoo lossis ua haujlwm tsis zoo. Txhawm rau tiv thaiv qhov teeb meem no, EMI tiv thaiv cov ntaub ntawv thiab cov kev daws teeb meem raug ua haujlwm los tiv thaiv kev cuam tshuam los ntawm kev cuam tshuam kev ua haujlwm ntawm cov khoom rhiab heev. Ib qho kev daws teeb meem zoo li no yog EMI fingerstock, cov khoom siv tiv thaiv ntau yam thiab txhim khu kev qha uas muab kev ua tau zoo heev. Nrog ntau tshaj 16 xyoo ntawm kev paub hauv EMI fingerstock manufacturing thiab ntau yam ntawm cov khoom siv EMI gasket, peb lub tuam txhab tau dhau los ua tus neeg muag khoom ntseeg siab hauv kev lag luam.

EMI fingerstock, tseem hu ua EMI shielding gaskets, muaj ib tug series ntawm conductive ntiv tes los yog springs, feem ntau yog ua los ntawm cov ntaub ntawv xws li beryllium tooj liab los yog stainless hlau. Cov ntiv tes no yog tsim los tsim kom muaj txoj hauv kev txuas ntxiv hluav taws xob, tsim kom muaj kev sib khi zoo tiv thaiv EMI emissions thiab tiv thaiv cov hluav taws xob hluav taws xob sab nraud los ntawm kev nkag los yog khiav tawm ntawm lub cuab yeej lossis lub qhov rooj. Lub fingerstock qhov yooj yim tso cai rau nws ua raws li qhov chaw tsis tu ncua thiab tswj kev sib cuag tas li, kom ntseeg tau tias muaj kev tiv thaiv zoo thiab txhim khu kev qha.

Ntawm peb lub tuam txhab, peb txaus siab rau peb cov kev paub dhau los thiab kev txawj ntse hauv EMI fingerstock manufacturing. Nrog ntau tshaj 16 xyoo ntawm kev lag luam muaj nyob, peb tau sau cov kev paub tseem ceeb thiab ua kom zoo dua peb cov txheej txheem kom xa cov khoom zoo tshaj plaws thiab kev ua tau zoo. Peb pab neeg ntawm cov kws tshaj lij tau paub zoo nyob rau hauv nuances ntawm EMI tiv thaiv cov cai thiab ua haujlwm rau siab ua kom tau raws li qhov xav tau ntawm peb cov neeg siv khoom.

Peb cov txheej txheem tsim khoom ua raws li cov lus qhia dav dav thiab tau txais txiaj ntsig zoo, kom ntseeg tau tias txhua EMI cov khoom lag luam ua tau raws li cov qauv nruj nruj. Los ntawm kev xaiv cov khoom mus rau qhov kawg tshuaj ntsuam xyuas, txhua kauj ruam yog ua tiav nrog precision thiab saib xyuas kom meej. Peb muab cov khoom siv zoo tshaj plaws, xws li qib high-qib beryllium tooj liab lossis stainless hlau, ua kom pom kev zoo thiab ua haujlwm ntev. Peb cov chaw tsim khoom hauv lub xeev siv cov tshuab thiab cov txheej txheem siab heev, tso cai rau peb los tsim cov ntiv tes sib txawv thiab ua tiav cov khoom zoo ib yam.

Raws li qhov tshwm sim ntawm peb txoj kev mob siab rau kev ua tau zoo, peb muab ntau yam ntawm ntau tshaj 300 tus qauv EMI gasket khoom. Cov no suav nrog ntau yam fingerstock profiles, qhov ntau thiab tsawg, thiab cov ntaub ntawv, tso cai rau peb cov neeg siv khoom nrhiav kev daws teeb meem zoo tshaj plaws rau lawv cov kev thov tshwj xeeb. Txawm hais tias nws yog rau cov khoom siv sib txuas lus, cov cuab yeej kho mob, lossis cov khoom siv hluav taws xob, peb muaj cov khoom siv EMI ntiv tes los daws koj cov kev xav tau kev tiv thaiv.

Ntxiv rau peb cov khoom tshwj xeeb, peb txaus siab rau peb tus kheej ntawm kev muab kev pabcuam zoo rau cov neeg siv khoom. Peb pab neeg muag khoom muag yeej ib txwm npaj los pab cov neeg siv khoom hauv kev nrhiav qhov zoo tshaj plaws EMI fingerstock tov thiab teb cov lus nug txog kev paub. Peb siv zog los tsim kom muaj kev sib raug zoo nrog peb cov neeg siv khoom mus sij hawm ntev, raws li kev ntseeg siab, kev ntseeg siab, thiab kev sib koom ua tiav.

Hauv kev xaus, peb lub tuam txhab coj ntau tshaj 16 xyoo ntawm kev paub thiab kev txawj ntse hauv EMI fingerstock manufacturing rau lub rooj. Nrog rau kev ua tiav cov txheej txheem ntws thiab ntau yam ntawm ntau tshaj 300 tus qauv EMI gasket khoom, peb muab cov kev coj ua zoo tshaj plaws thiab kev tiv thaiv kev ruaj ntseg rau ntau yam kev lag luam. Txawm hais tias koj xav tau cov khoom lag luam tawm ntawm lub txee lossis cov kev daws teeb meem, peb pab neeg tau npaj los pab koj nrhiav EMI fingerstock zoo meej rau koj daim ntawv thov. Cia siab rau peb cov kev paub dhau los, kev ua tau zoo, thiab kev cog lus kom xa cov kev daws teeb meem zoo tshaj plaws EMI kom tau raws li koj xav tau.

Khoom tsim nyog

Kev tsim cov txheej txheem ntws ntawm BeCu Fingerstock

Cov khoom siv tsim khoom

Lub luag haujlwm tseem ceeb:

Feem ntau tsim BeCu EMI Fingerstock, BeCu Kauv Tube, SMD caij nplooj ntoos hlav, BeCu Caij nplooj ntoos hlav, EMC chav Fingerstock thiab meej stamping qhov chaw, thiab lwm yam.

Cov khoom siv ntawm kev tsim khoom stamping:

Ceev ceev tshuab los ntawm Micron TaiWan: 30 Tuj 2 teeb.

Ceev ceev tshuab los ntawm Micron TaiWan: 40 Tuj 1 poob lawm.

Xovxwm tshuab: 25 Tuj 10sets Tsim los ntawm XuZhou Pressing Tshuab Hoobkas

Xovxwm tshuab: 40 Tuj 10sets Tsim los ntawm XuZhou Pressing Tshuab Hoobkas

Xovxwm tshuab: 63 Tuj 4sets Tsim los ntawm XuZhou Pressing Tshuab Hoobkas

Tapping tshuab: 1set

Lub tshuab ntxhua khaub ncaws: 1set

Lwm yam khoom siv: 7sets

Kev kub ceev Punching tshuab:

Cov txheej txheem tswj kom zoo

I.Environmental Requirements rau cov khoom

Peb cov khoom caij nplooj ntoos hlav BeCu ua tau raws li qhov yuav tsum tau ua ntawm SGS daim ntawv qhia, ROHS daim ntawv qhia, REACH, Halogen-dawb (HF) daim ntawv qhia, thiab lwm yam.

II.Muab daim ntawv ntsuam xyuas cov khoom tiav

Cov neeg siv khoom tuaj yeem muab cov lus ceeb toom hauv qab no thaum xa khoom lossis

xa cov qauv:

• Daim ntawv tshaj tawm kev tshuaj xyuas. • SGS qhia txog cov khoom siv raw.

• Cov ntaub ntawv pov thawj. • Daim ntawv qhia txog kev kho cua sov.

• Electroplating ROHS tsab ntawv ceeb toom. • Electroplating zaj duab xis thickness qhia.

• Daim ntawv qhia txog tshuaj tsuag ntsev. • Plating txheej ntog tawm daim ntawv qhia.

• Daim ntawv qhia txog Elastic rov qab kuaj. • Compression force report, thiab lwm yam.

III.Cov cuab yeej kuaj xyuas zoo

Peb muaj tag nrho cov khoom kuaj cov cuab yeej los xyuas kom meej tias cov khoom tsis zoo raws li cov neeg siv khoom xav tau. Qee yam ntawm cov cuab yeej kuaj xyuas yog raws li hauv qab no:

Qhov projector

Hardness Tester

Ntsev tshuaj ntsuam tshuab

X-ray thickness meter

ATLAS tiv thaiv combustion tester

FT-300Ib qho kev ntsuas ntsuas

Xa, shipping thiab pab

FAQ

Cov lus nug thiab cov lus teb ntawm cov txheej txheem tsim khoom thiab thev naus laus zis

Q1: Dab tsi yog cov txheej txheem ntawm peb cov khoom hais?

A1: Tom qab tau txais daim duab tsis zoo lossis qauv los ntawm cov neeg siv khoom, Peb lub tuam tsev engineering yuav muab cov khoom hauv qab no rau kev tshuaj xyuas.

cov ntaub ntawv

Cov txheej txheem tsim khoom (xws li electroplating thiab tom qab txheej txheem)

qhov kam rau ua

txoj kev ntsuas

pob khoom, thiab lwm yam

Q2: Ntev npaum li cas peb tuaj yeem muab cov lus hais tom qab tau txais cov neeg siv khoom kos duab lossis cov qauv?

A2: Yog tias tsis muaj qhov yuam kev ntawm koj daim duab, peb lub tuam txhab feem ntau muab cov lus hais hauv 2 teev.

Q3: Tus qauv tsim qauv ntawm peb tus qauv BeCu Fingerstock yog dab tsi?

A3: BeCu Fingerstock txaus siab rau qhov muaj zog hloov pauv, peb cov khoom lag luam xa mus rau tus qauv thoob ntiaj teb ntawm BeCu Fingerstock kom paub meej cov qauv tsim nyog thiab kev tiv thaiv kev ua haujlwm.

Q4: Yuav ua li cas xam qhov ntev ntawm cov khoom?

A4: qhov ntev ntawm cov khoom: L=pitch * pitch nodes-qhov dav.Vim qhov tshwj xeeb ntawm cov khoom siv los ua cov lej suav ntawm ntu (piv txwv li MB-1216-01. Length: L=4 7586-0 45=408mm)

Q5: Peb muaj ntau tshaj 50 tus qauv khoom ntawm Fingerstock nyob rau hauv shielding chav ntawm peb lub tuam txhab. Peb puas tuaj yeem tsim cov qauv tshwj xeeb rau cov neeg siv khoom?

A5: Yog, Peb lub tuam txhab tuaj yeem hloov kho kom haum rau peb cov cuab yeej

Raws li cov neeg siv khoom xav tau, thiab tom qab ntawd peb tuaj yeem ua cov qauv khoom tsim los ntawm cov neeg siv khoom.

Cim npe nrov: Tuam Tshoj EMI fingerstock manufacturers, lwm tus neeg, Hoobkas